直線振動篩特點

ZS系列直線振動篩應用自同步振動原理,采用振動電機作為振源,橡膠彈簧作為減振器及高耐磨材質作篩板,偏心壓緊密封等,具有壽命長、噪音低、篩分效率高等特點。直線振動篩用途

ZS系列直線振動篩適用于燒結礦、自然礦、焦炭及其它粉狀物料的高效篩分,直線振動篩廣泛應用于冶金、礦山、煤炭、建材等行業。

直線振動篩型號及參數

型號 | 篩面規格mm(長×寬) | 篩面層數 | 入料粒度(mm) | 篩孔尺寸(mm) | 振幅(mm) | 篩面傾角(°) | 振動電機 | 外形尺寸mm(長×寬×高) | ||

型號 | 功率(kw) | 頻率(r/min) | ||||||||

ZS0615 | 1500×600 | 1 | <150 | 3 5 1 15 20 25 50 | 5-7 | 0-15可調 | ZG612 | 2×0.75 | 1000 | 2035×1070×1340 |

2ZS0615 | 2 | ZG612 | 2×0.75 | 2035×1070×1430 | ||||||

ZS0918 | 1800×900 | 1 | ZG625 | 2×1.5 | 2200×1420×1570 | |||||

2ZS0918 | 2 | ZG625 | 2×1.5 | 2200×1420×1660 | ||||||

ZS1224 | 2400×1200 | 1 | ZG636 | 2×2.2 | 2793×1800×1770 | |||||

2ZS1224 | 2 | ZG645 | 2×3 | 2793×1800×1860 | ||||||

ZS1230 | 3000×1200 | 1 | ZG660 | 2×4 | 3250×1800×2200 | |||||

2ZS1230 | 2 | Yzo-63-6 | 2×4.5 | 3250×1800×2290 | ||||||

ZS1530 | 3000×1500 | 1 | Yzo-63-6 | 2×4.5 | 3400×2220×2130 | |||||

2 ZS1530 | 2 | Yzo-80-6 | 2×5.5 | 3400×2220×2220 | ||||||

ZS1536 | 3600 ×1500 | 1 | Yzo-80-6 | 2×5.5 | 4050×2160×2120 | |||||

2ZS1536 | 2 | Yzo-80-6 | 2×5.5 | 4050×2160×2210 | ||||||

ZS1836 | 3600 ×1800 | 1 | <180 | 5-15可調 | Yzo-130-6 | 2×7.5 | 400×2520×2210 | |||

2ZS1836 | 2 | Yzo-130-6 | 2×7.5 | 400×2520×2300 | ||||||

ZS1842 | 1200 ×1800 | 1 | Yzo-130-6 | 2×7.5 | 4864×2600×2400 | |||||

2ZS1842 | 2 | Yzo-130-6 | 2×7.5 | 4864×2600×2500 | ||||||

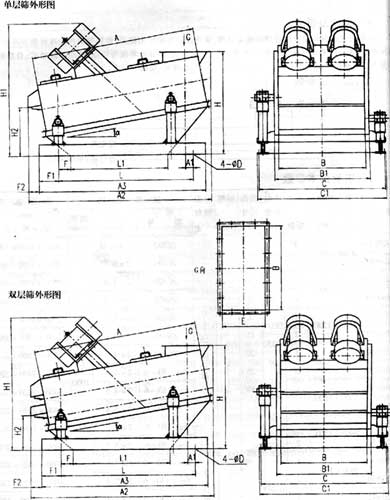

直線振動篩安裝尺寸

單層直線振動篩外形圖

型號 | A | A1 | A2 | A3 | B | B1 | C | C1 | L | L1 | F | F1 | F2 | H | H1 | H2 | E | ΦD | α |

ZS0615 | 1500 | -40 | 2035 | 1500 | 600 | 680 | 1040 | 1070 | 1300 | 1050 | -30 | 200 | 290 | 1040 | 1340 | 290 | 450 | 17 | 7° |

2ZS0615 | 1500 | -40 | 2035 | 1500 | 600 | 680 | 1040 | 1070 | 1300 | 1050 | -30 | 200 | 290 | 1130 | 1430 | 200 | 450 | 17 | 7° |

ZS0918 | 1800 | 150 | 2200 | 1900 | 900 | 1060 | 1384 | 1420 | 1600 | 1100 | 120 | 150 | 265 | 1250 | 1570 | 400 | 600 | 17 | 10° |

2ZS0918 | 1800 | 150 | 2200 | 1900 | 900 | 1060 | 1384 | 1420 | 1600 | 1100 | 120 | 150 | 265 | 1340 | 1660 | 230 | 600 | 17 | 10° |

ZS1224 | 2400 | 50 | 2793 | 2300 | 1200 | 1380 | 1756 | 1800 | 2100 | 1500 | 80 | 200 | 253 | 1460 | 1770 | 520 | 800 | 21 | 10° |

2ZS1224 | 2400 | 50 | 2793 | 2300 | 1200 | 1380 | 1756 | 1800 | 2100 | 1500 | 80 | 200 | 253 | 1550 | 1860 | 400 | 800 | 21 | 10° |

ZS1230 | 3000 | 370 | 3250 | 2890 | 1200 | 1356 | 1756 | 1800 | 2690 | 1200 | 200 | 320 | 270 | 1950 | 2200 | 700 | 800 | 21 | 15° |

2ZS1230 | 3000 | 370 | 3250 | 2890 | 1200 | 1356 | 1756 | 1800 | 2690 | 1200 | 200 | 320 | 270 | 2040 | 2290 | 480 | 800 | 21 | 15° |

ZS1530 | 3000 | 170 | 3400 | 3000 | 1500 | 1700 | 2160 | 2220 | 2540 | 1650 | 250 | 300 | 280 | 1730 | 2130 | 660 | 900 | 25 | 10° |

ZS1536 | 3600 | -140 | 4050 | 3200 | 1500 | 1700 | 2100 | 2160 | 2700 | 2420 | 0 | 250 | 450 | 1840 | 2120 | 600 | 1000 | 25 | 10° |

2ZS1536 | 3600 | -140 | 4050 | 3200 | 1500 | 1700 | 2100 | 2160 | 2700 | 2420 | 0 | 250 | 450 | 1930 | 2210 | 290 | 1000 | 25 | 10° |

ZS1836 | 3600 | 20 | 4000 | 3200 | 1800 | 1920 | 2480 | 2520 | 2950 | 2360 | 0 | 250 | 370 | 1770 | 2210 | 700 | 1000 | 25 | 10° |

2ZS1836 | 3600 | 20 | 4000 | 3200 | 1800 | 1920 | 2480 | 2520 | 2950 | 2360 | 0 | 250 | 370 | 1860 | 2300 | 440 | 1000 | 25 | 10° |

ZS1842 | 4200 | 196 | 4864 | 4000 | 1800 | 1980 | 2480 | 2520 | 3800 | 2840 | 96 | 496 | 40 | 1960 | 2400 | 900 | 1200 | 25 | 10° |

2ZS1842 | 4200 | 196 | 4864 | 4000 | 1800 | 1980 | 2480 | 2520 | 3800 | 2840 | 96 | 496 | 40 | 2050 | 2490 | 600 | 1200 | 25 | 10° |